Transport System Bögl - all from a single source

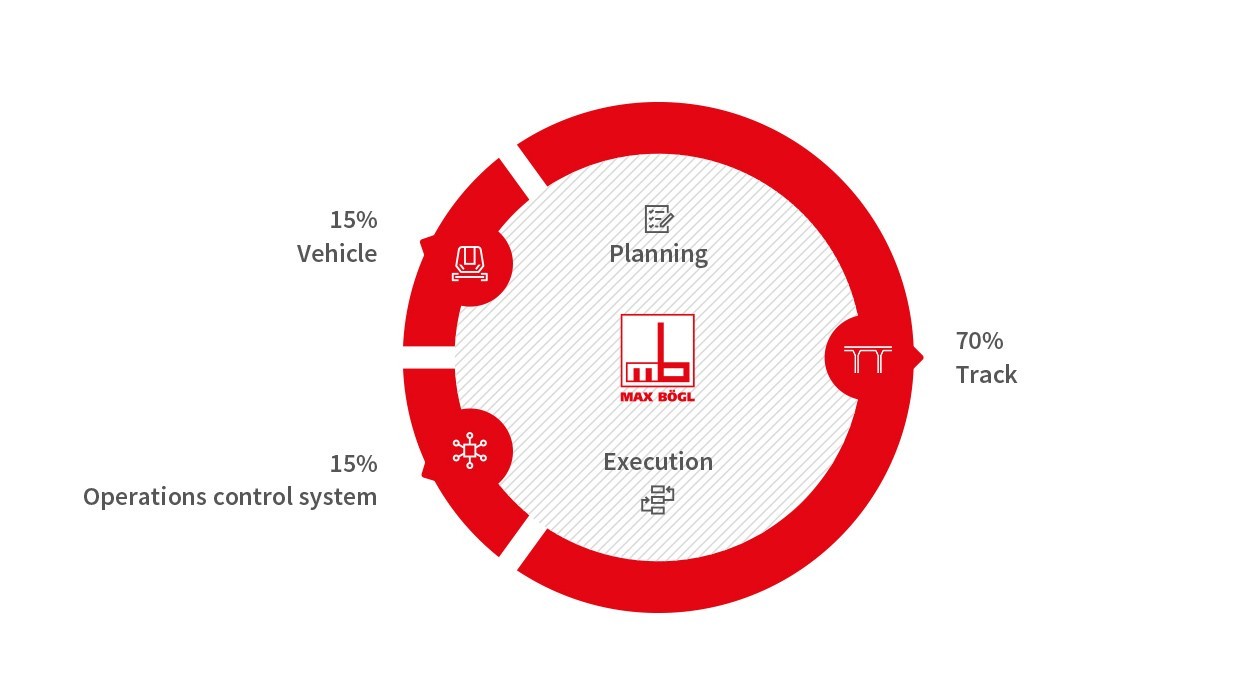

Complex infrastructure projects are especially cost-effective if most of the individual work steps can be carried out by a single source. As the full-service provider of the Transport System Bögl, we are able to implement all processes in a standardized and coordinated manner: from planning and the industrial manufacturing of guideways and vehicles to the application of structural measures and implementation of our own operational control technology.

Economic overall project

Efficient construction process

Premium quality production and assembly

The Transport System Bögl and its individual components, track and vehicle, are produced and assembled in Sengenthal. The concrete segments of the track are cast in flexible formworks and then ground with a precision of less than one millimeter using a CNC grinding machine. With the help of expert personnel and state-of-the-art technology, the running gear and car bodies are assembled here to form the TSB. The magnet unit – the heart of the vehicle – is also assembled during this stage of production. A smart digital storage system ensures the availability of individual parts for each individual production step. The individual components are then loaded into standard shipping containers and delivered for use around the world.

Operational control technology for automatic driving

The operational control system of the Transport System Bögl includes components and functions for safeguarding, monitoring and controlling operation. It links the vehicle, guideway switch, station and power supply subsystems to form a complete system that is ready for operation and allows fully automatic operation with short train headway times. All subsystems can be completely controlled and monitored from the control center. Core functions are the safety features, which meet the highest safety integrity level (SIL4) for railway standards, and a high-availability data transmission system.