Sustainable freight transportation, quickly implementable

For efficient freight transportation between highly frequented container hubs, port terminals, and their connection to surrounding distribution centres, rail-based transport systems can be a sustainable alternative.

Thanks to its state-of-the-art magnetic levitation (maglev) technology, TSB Cargo offers the right solution. Fully automated processes ensure high performance with maximum redundancy. From the design to the industrial production of the components, the on-site assembly to the operation of the system: With TSB Cargo, Max Bögl delivers an efficient, turnkey completesystem that redefines the future of freight transport.

Sustainable and reliable logistics chains

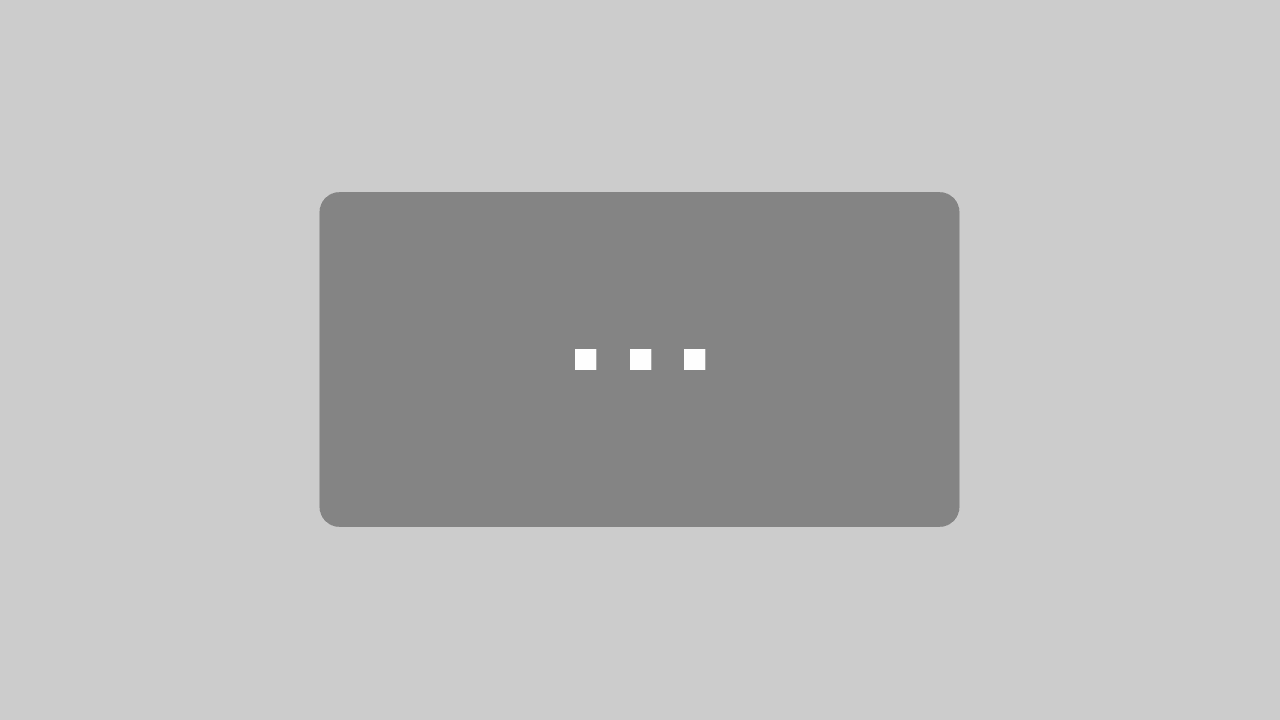

Fully automated operation in combination with the maglev technology used ensures efficient, economical, reliable, and low-emission transport.

Quiet, low-wear, and redundant are characteristics that distinguish the TSB, and contribute to resilient logistics chains.

Areas of application

Highly frequented short and medium distances, such as the connection of port terminals to each other or to hinterland hubs, can be reliably linked with TSB Cargo.

This allows delivery processes to be consolidated, container depots to be relocated to the hinterland, and thus relieve the road, port, and terminal infrastructure.

Low-emission and reliable transport with the TSB can reduce truck traffic significantly.

Flexible and demand-oriented

With its flexible system parameters, the TSB Cargo can adapt to any challenge.

|

Operating Speed |

up to100 mph/h |

|

Acceleration |

0.13 g |

|

Horizontal Curve radius |

up to 148 ft |

|

Superelevation |

up to 8° |

|

Grade |

up to 10% |

|

Headway |

min. 25 s |

|

Transportkapazität |

Bis zu 180 Container/Fahrspur |

|

Power distribution system |

750 V DC |

|

Capacity |

up to 180 containers/hour/direction |

High-quality infrastructure that can be implemented quickly

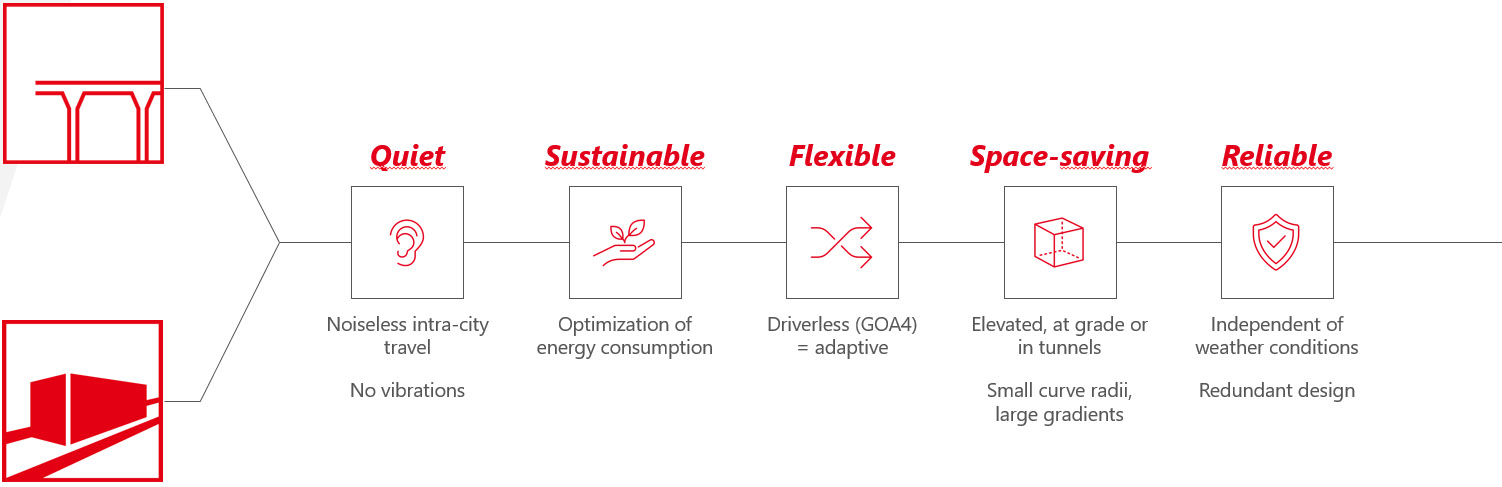

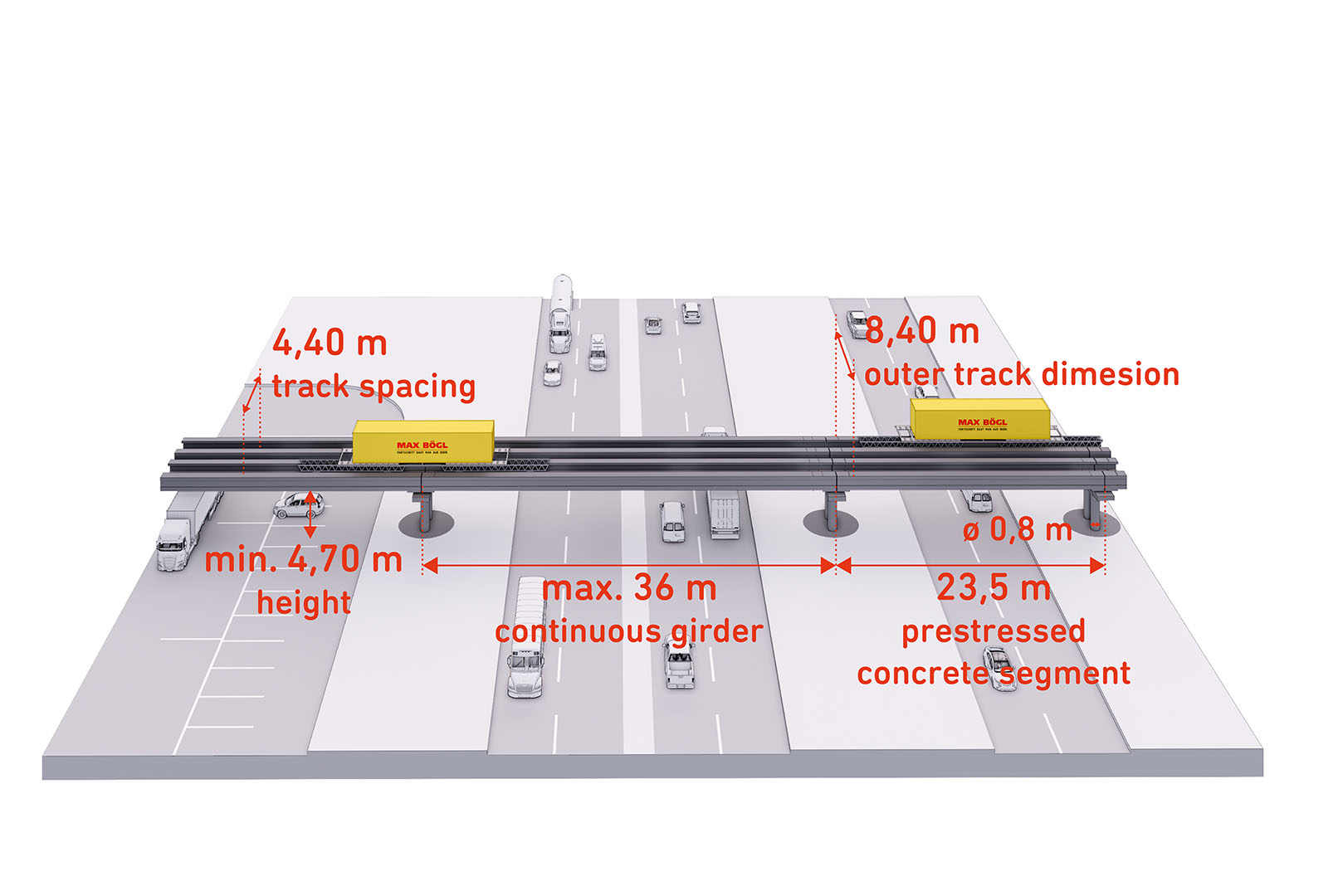

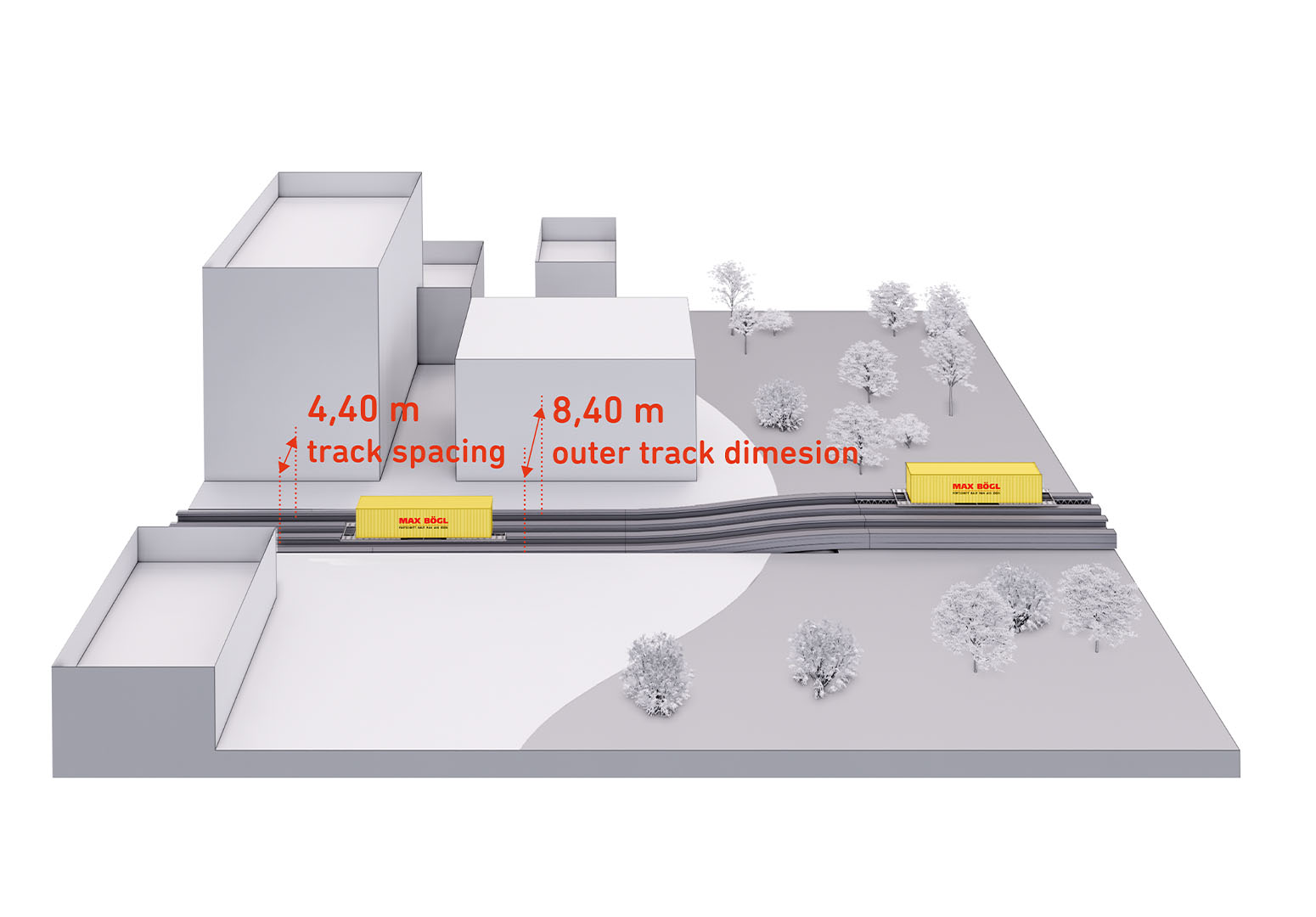

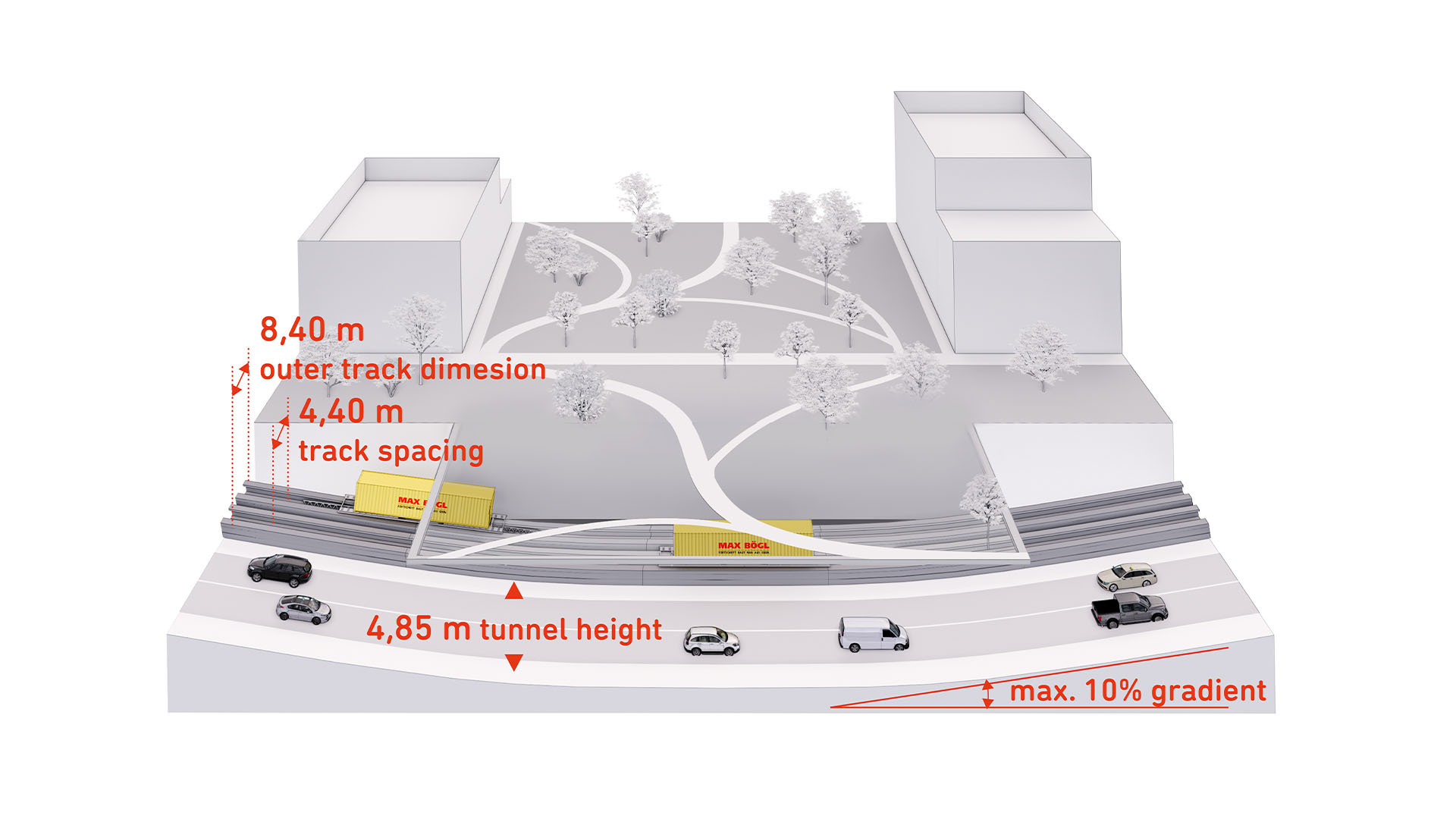

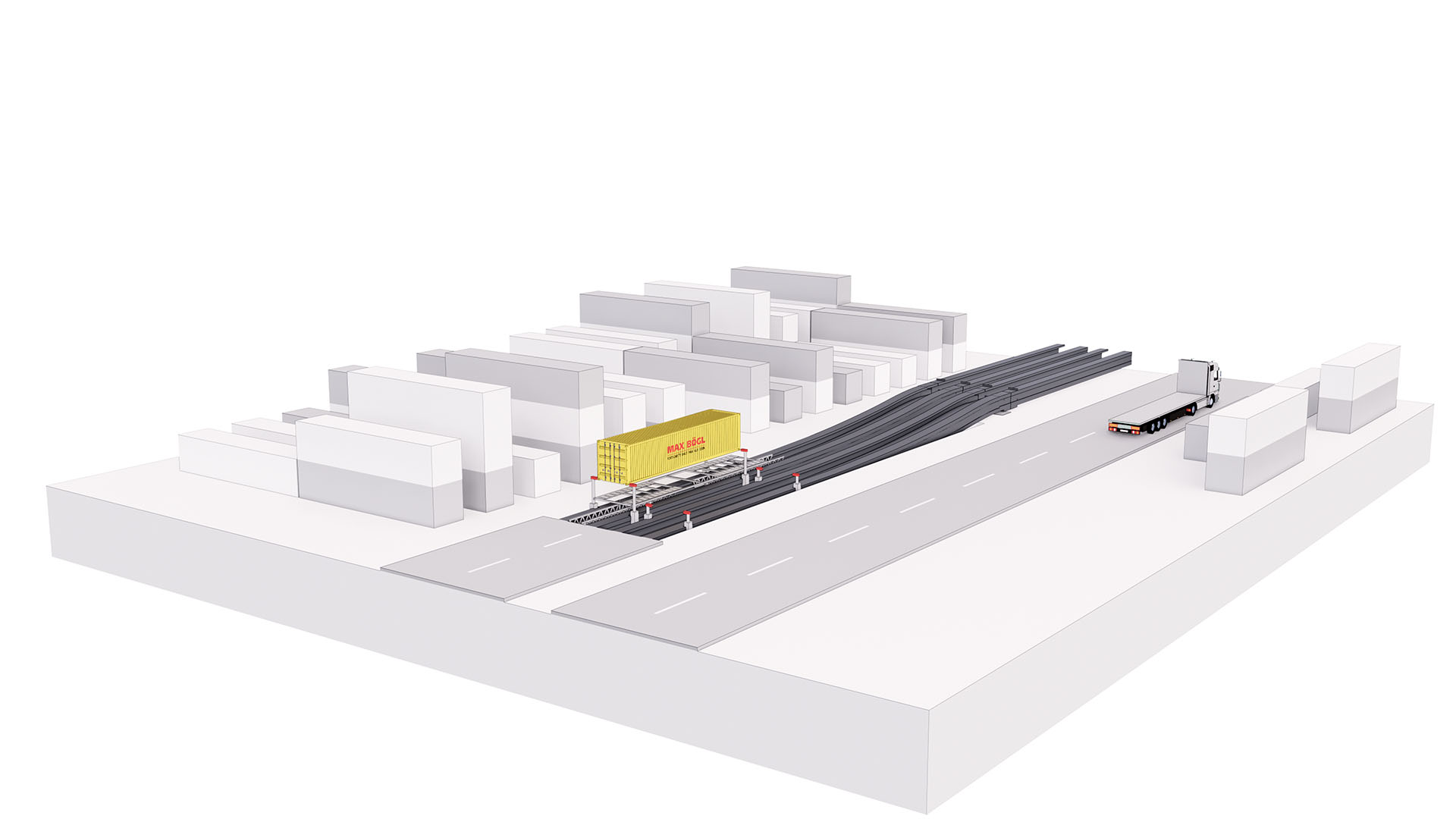

The aesthetic track layout adapts to the respective surroundings and no overhead lines are necessary.

The track can be at grade, underground or elevated. The loads are applied along the entire length of the vehicle, thus enabling a slender and cost-efficient primary supporting structure. Due to their standardized lengths, the track segments fit into 40-foot containers, and can be shipped worldwide from central production facilities.

The industrial prefabrication allows short realization times. Future projects can be realized quickly, resource-efficiently, and economically with the TSB Cargo.

Highway

Bridge

Flush

Tunnel

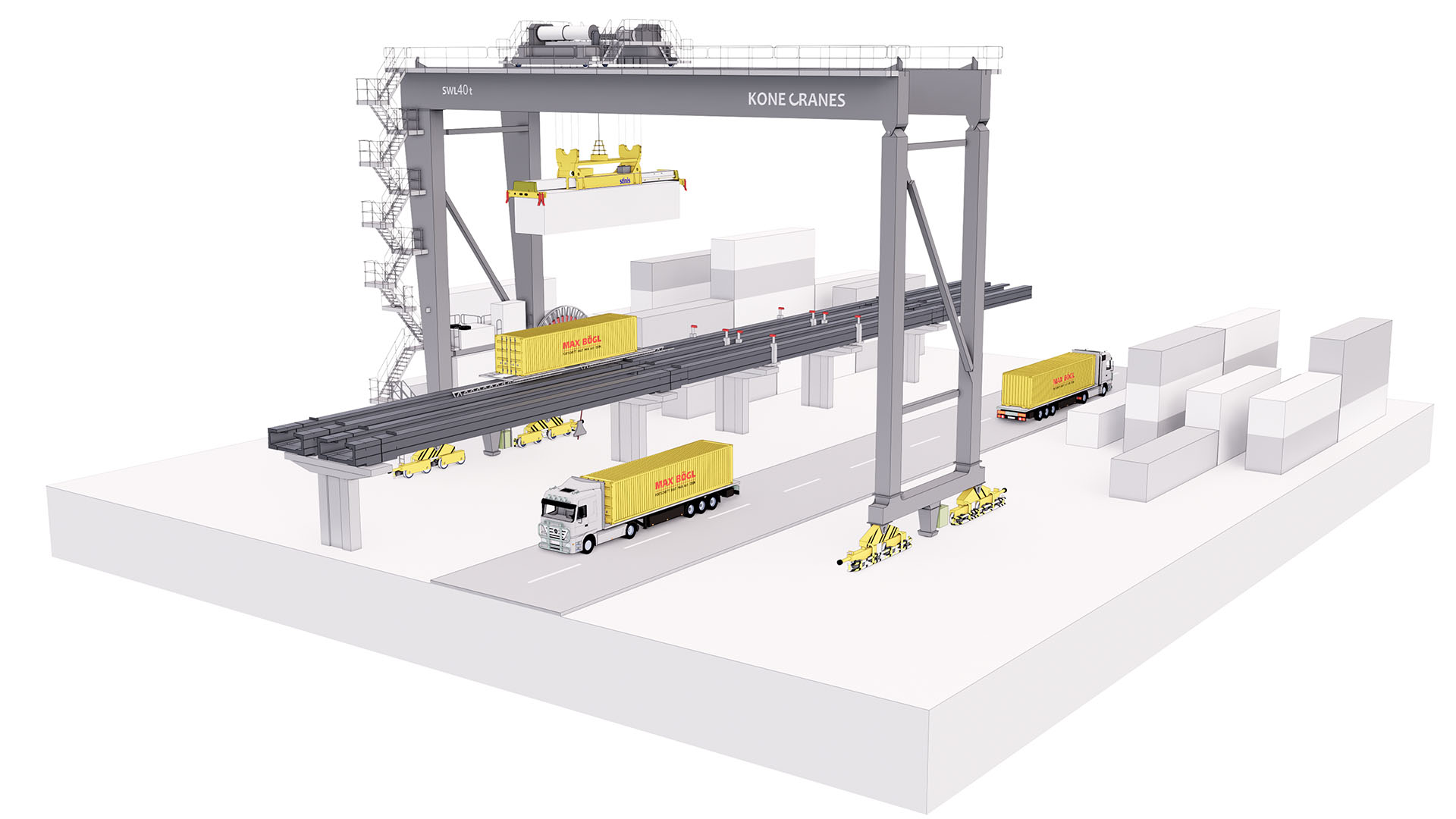

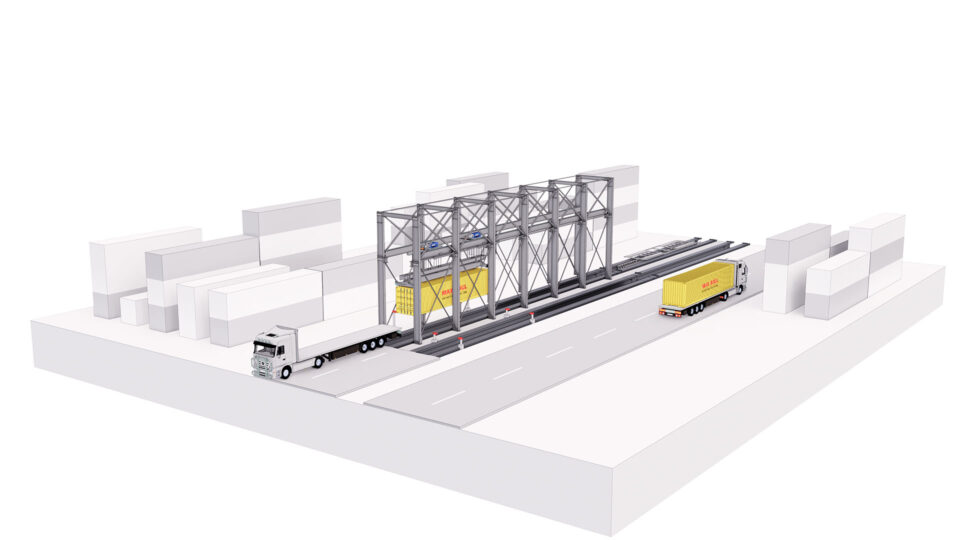

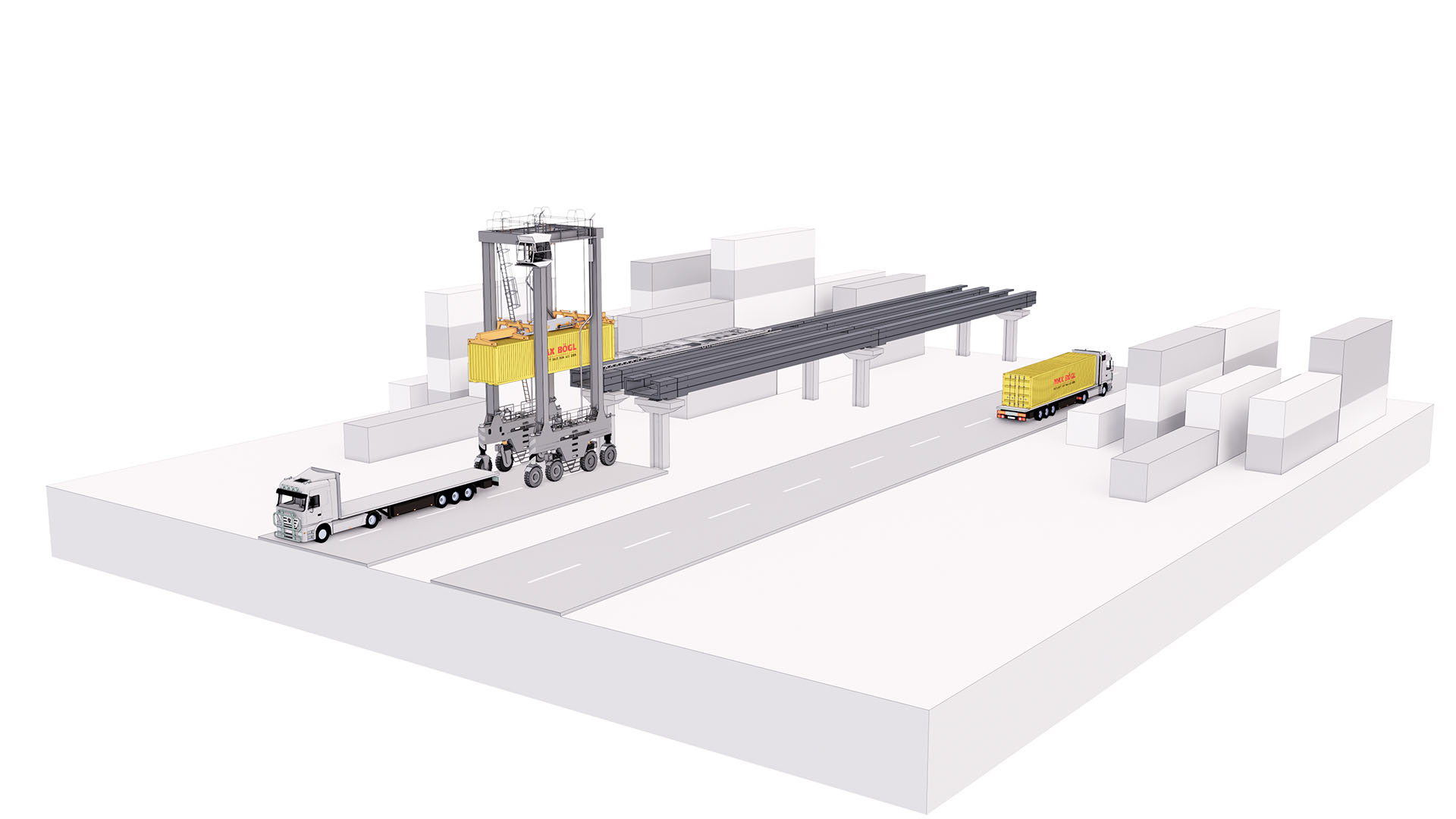

Reliable and simple transshipment processes

A transshipmentsolution specially configured for the TSB Cargo enables the individual vehicles to be loaded and unloaded efficiently with existing lifting infrastructure -without delays in the transshipment process.

Modular parallelization of multiple transshipment points allows optimal adaptation of the transshipment process cycle to the demand-based vehicle cycle.

At the transshipment point, a hydraulic device separates the interfaces between the lifting device and the TSB Cargo vehicles. This also serves as a buffer device.

The advantage is that there are no direct dependencies between the vehicle and the lifting device in the entire transportation process. This devicecanunloadconventionalfreighttrucksdirectly.

Transhipment with intermediate storage

Transshipment gantry crane elevated

Crane transshipment

Transhipment Carrier

Complete system solution from a single source

As afull-service provider of TSB Cargo, Max Bögl implements all processes in a standardized and coordinated manner: from the conceptualdesign to the industrial production of the track and the vehicle, to the realization of the construction works, and the implementation of the operations control system developed in-house.

As an experienced construction company, we can draw on sound expertise, and many years of experience in handling large-scale projects. We can also operate the transportation system on demand.

Tested and ready for use

The TSB Cargo was presented to international experts for the first time in October 2021on a purpose-built demonstration line at the ITS World Congress in Hamburg.

With a project duration of onlyfour months from design to commissioningof the 120 m long demonstration line, the integrated planningapproach, and the modularconstruction of the infrastructure proved their advantages. The GermanFederal Ministry of Transport funded the project to develop and test alternative technologyfor reliable, environmentally friendly, sustainable, and efficient freight transportation. Possible applications are being examined in a feasibility study together with the Port of Hamburg.